Insulated Welding Cables

Insulated Welding Cables Specification

- Phase

- Single/Three Phase (as per connection)

- Welding

- Power Consumption

- Depends on Welding Operation

- Diameter

- Available in various diameters as per specification

- Power Source

- Electrical

- Output Voltage

- Depends on Supply (generally up to 1100V)

- Current Range

- 100A to 600A

- Automation Grade

- Manual

- Frequency

- 50/60 Hz

- Application

- Industrial Welding, Fabrication, Construction, Shipbuilding, Automobile Workshops

- Equipment Type

- Welding Cable

- Type

- Insulated Welding Cables

- Condition

- New

- Material

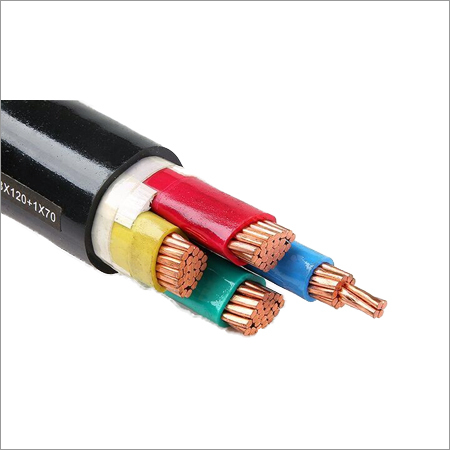

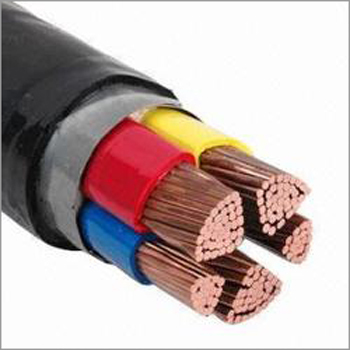

- Copper Conductor, PVC Insulation

- Power

- Suitable for Welding Applications (Power handled depends on cable size)

- Voltage

- Up to 1100V

- Dimensions

- Standard Lengths (Available in coils or reels, e.g., 100m)

- Input Voltage

- Up to 1100V

- Rated Current

- Varies by Cable Size (e.g., 100A to 600A)

- Rated Capacity

- Depends on Cross-sectional Area

- Tensile Strength

- High

- Flame Retardant

- Yes

- Usage Environment

- Indoor and Outdoor use

- Packaging

- Coil, Roll, or Drum

- Insulation Material

- Flexible PVC

- Minimum Bending Radius

- 6 x Cable Diameter (approx)

- Conductor Type

- Stranded Copper

- Resistance to Oil & Chemicals

- Yes

- Color

- Black / Red / Yellow (depends on manufacturer)

- Outer Sheath

- Abrasion and Chemical Resistant PVC

- Flexibility

- High Flexibility for Easy Handling

- Temperature Resistance

- -20°C to +70°C (typical)

Insulated Welding Cables Trade Information

- Minimum Order Quantity

- 10 Meters

- Supply Ability

- 100 Meters Per Day

- Delivery Time

- 1 Week

About Insulated Welding Cables

Exceptional Flexibility for Seamless Handling

These welding cables feature stranded copper cores encased in flexible PVC insulation, ensuring easy maneuverability during fabrication and installation. Their high flexibility allows for effortless routing and bends, facilitating smooth connectivity in challenging work areas without compromising cable integrity.

Robust Construction for Harsh Environments

Built to withstand abrasion, chemicals, oil, and flames, the outer PVC sheath ensures prolonged cable life in industrial settings. The cables are suitable for both indoor and outdoor use, making them ideal for shipbuilding, construction, automobile workshops, and fabrication projects where durability and resistance are imperative.

Reliable Performance in Extreme Temperatures

Engineered to operate efficiently from -20C up to +70C, these insulated welding cables support consistent and safe operation under varying temperature conditions. The robust materials protect the conductor and maintain cable flexibility, even in adverse climates or high-heat environments.

FAQs of Insulated Welding Cables:

Q: How can insulated welding cables be handled during installation?

A: Insulated welding cables are designed with high flexibility, making them easy to maneuver, route, and bend during installation in tight spaces. Always observe the recommended minimum bending radius, which is approximately six times the cable diameter, to maintain cable integrity.Q: What are the typical applications for these insulated welding cables?

A: These cables are commonly used in industrial welding, fabrication, construction, shipbuilding, and automobile workshops. They are suitable for Arc, MIG, TIG, and other welding processes that require secure electrical connectivity and reliable current handling.Q: When should I use cables with flame retardant and chemical resistant properties?

A: Flame retardant and chemical resistant cables are essential in environments where exposure to high temperatures, oil, chemicals, or potential fire hazards exists. They help protect against accidents and maintain safety standards in demanding industrial or fabrication settings.Q: Where can these welding cables be deployed for maximum efficiency?

A: These insulated welding cables are suitable for both indoor and outdoor use, including industrial plants, workshop floors, construction sites, and shipyards. Their robust design ensures stable performance in various environmental conditions.Q: What benefits does using a flexible PVC insulated welding cable offer?

A: Flexible PVC insulation provides enhanced maneuverability, easier handling, and resistance to abrasion, chemicals, and flame. This ensures long-lasting performance and safety, especially in dynamic and high-stress industrial applications.Q: What is the process for selecting the right cable size for my welding operation?

A: Select the cable size based on your required current range (100A to 600A) and voltage (up to 1100V). Ensure compatibility with your welding equipment, and consult manufacturer specifications or your supplier to match cable cross-sectional area and rated capacity with your application needs.Q: How are these cables typically packaged and supplied in India?

A: Welding cables are distributed by suppliers and traders in India, typically packaged in coils, rolls, or drums. Standard lengths such as 100 meters are available to suit various industrial and commercial requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welding Cables and Hose Pipes Category

PVC Insulated Power Cables

Price 1 INR

Minimum Order Quantity : 10 Meters

Material : Copper/Aluminium Conductor, PVC Insulated

Automation Grade : Manual Installation

Dimensions : Varies (as per customer requirement)

Condition : New

Insulated Power Cables

Price 1 INR

Minimum Order Quantity : 10 Meters

Material : Copper Conductor, PVC Insulation

Automation Grade : Manual Installation

Dimensions : Custom, as per requirement

Condition : New

House Wiring Cables

Price 1 INR

Minimum Order Quantity : 10 Meters

Material : Copper Conductor, PVC Insulated

Automation Grade : Manual Installation

Dimensions : Standard Coil 90 meters

Condition : New

Gas Cutting Hose Pipe

Price 1 INR

Minimum Order Quantity : 10 Meters

Material : Synthetic Rubber with Reinforcement

Automation Grade : Manual

Dimensions : Standard Length 8 meters or custom

Condition : New

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese