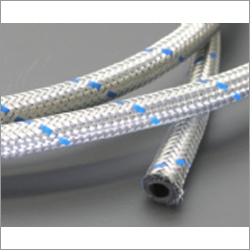

Gas Cutting Hose Pipe

Gas Cutting Hose Pipe Specification

- Welding

- Suitable for Gas Welding/Cutting

- Automation Grade

- Manual

- Application

- Gas Cutting, Welding, Industrial Use

- Equipment Type

- Industrial Welding Accessory

- Diameter

- Typically 6 mm or 8 mm inner diameter

- Type

- Gas Cutting Hose Pipe

- Condition

- New

- Material

- Synthetic Rubber with Reinforcement

- Dimensions

- Standard Length 8 meters or custom

- Outer Cover

- Abrasion, Weather, and Flame resistant

- Odour

- Odourless synthetic rubber

- Weight

- Lightweight and easy to maneuver

- Flexibility

- High flexibility for ease of handling

- Color

- Red and Blue (for Oxygen and Acetylene) or as required

- Working Pressure

- 10 Bar (Max)

- Burst Pressure

- 30 Bar

- Packaging

- Roll packed or as specified

- End Fittings

- Brass Fittings/Clamp as per request

- Reinforcement

- High-strength synthetic yarn

- Temperature Range

- -20C to +70C

Gas Cutting Hose Pipe Trade Information

- Minimum Order Quantity

- 10 Meters

- Supply Ability

- 100 Meters Per Day

- Delivery Time

- 1 Week

About Gas Cutting Hose Pipe

Distinctive Color Coding for Safety

The hose comes in clear red and blue colors, making identification between oxygen and acetylene lines straightforward and enhancing workplace safety. This color distinction minimizes the risk of accidental mix-ups during setup or operation, ensuring compliance with industry standards.

Durable and Flexible Construction

Manufactured with high-strength synthetic yarn reinforcement and an abrasion, weather, and flame-resistant outer cover, the hose offers both strength and adaptability. Designed to withstand rigorous industrial use, its flexibility enables easy routing and handling, reducing labor effort during installation and operation.

Customizable for Various Requirements

Available in standard 8-meter rolls, the hose can also be tailored to specific length and fitting demands. Brass end fittings or clamps are provided as per user requirements, enabling seamless integration with existing welding setups. Packaging is adaptable, ensuring safe transportation and handling.

FAQs of Gas Cutting Hose Pipe:

Q: How does the color coding on the hose pipe enhance safety during gas cutting and welding?

A: The red and blue color coding distinctly identifies the hoses for oxygen and acetylene, reducing the risk of connecting the wrong gases. This minimizes operational errors and improves workplace safety by adhering to established industrial conventions.Q: What is the process for installing the Gas Cutting Hose Pipe in a welding setup?

A: Installation involves connecting the hose to gas regulators and welding equipment using brass fittings or clamps, as specified. The hoses high flexibility eases routing, while its reinforced structure ensures a secure and leak-free connection throughout the setup.Q: Where is this hose pipe typically used and what are its main applications?

A: This hose is primarily used in industrial environments for gas cutting and welding operations. It serves applications in metal fabrication, manufacturing, construction, and other sectors requiring precise gas flow for safe, efficient welding and cutting.Q: What are the benefits of using this hose pipe over conventional options?

A: Benefits include high flexibility for easy handling, durable construction with weather and flame resistance, odorless material for a cleaner work atmosphere, and lightweight design for enhanced maneuverability. Custom lengths and fittings further add to its versatility and practicality.Q: When should a user consider replacing their gas cutting hose pipe?

A: Replacement is recommended if there are visible abrasions, cracks, or signs of wear on the hose or fittings, if flexible performance decreases, or if leakages occur during operation. Regular inspection ensures optimal safety and function.Q: What material is used for reinforcement, and how does it affect hose performance?

A: The hose is reinforced using high-strength synthetic yarn, which provides robustness against high pressures, prevents kinking, and maintains flexibility. This reinforcement increases the hoses durability and operational reliability even under demanding industrial conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welding Cables and Hose Pipes Category

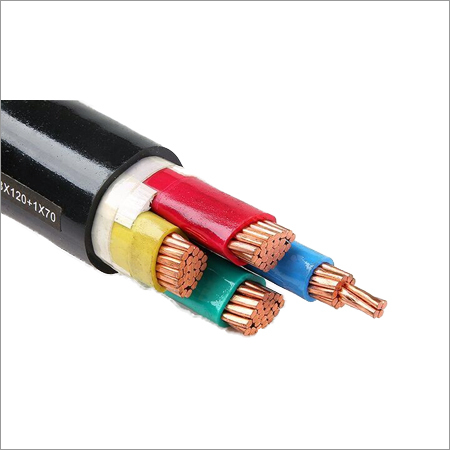

Insulated Welding Cables

Price 1 INR

Minimum Order Quantity : 10 Meters

Automation Grade : Manual

Application : Industrial Welding, Fabrication, Construction, Shipbuilding, Automobile Workshops

Equipment Type : Welding Cable

Diameter : Available in various diameters as per specification

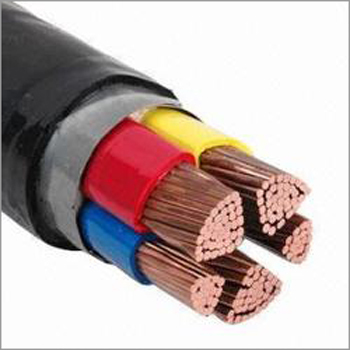

Insulated Power Cables

Price 1 INR

Minimum Order Quantity : 10 Meters

Automation Grade : Manual Installation

Application : Power Distribution, Industrial, Residential, Commercial

Equipment Type : Electrical Power Cable

Diameter : Available from 1.5 sq mm to 400 sq mm

House Wiring Cables

Price 1 INR

Minimum Order Quantity : 10 Meters

Automation Grade : Manual Installation

Application : Domestic and commercial wiring

Equipment Type : Electrical Cable

Diameter : Standard sizes: 0.5 mm to 6 mm

SS Flexible Hose Pipe

Price 1 INR / Meter

Minimum Order Quantity : 10 Meters

Automation Grade : Manual

Application : Plumbing, Gas, Chemical Transfer, HVAC, Industrial Applications

Equipment Type : SS Flexible Hose

Diameter : 1/4 inch to 12 inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese