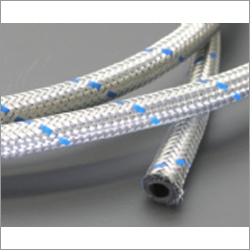

Rubber Welding Hoses

Rubber Welding Hoses Specification

- Welding

- Gas Welding

- Application

- Welding Equipment, Industrial Gas Conveyance

- Equipment Type

- Welding Hose

- Diameter

- 6 mm, 8 mm, 10 mm (options available)

- Automation Grade

- Manual

- Type

- Rubber Welding Hose

- Condition

- New

- Material

- Synthetic Rubber

- Dimensions

- Customizable

- Color

- Red (for Acetylene), Blue (for Oxygen)

- Reinforcement

- High tensile synthetic yarn

- Tube

- Smooth, weather and abrasion resistant

- Working Pressure

- up to 20 bar

- Length

- Standard 15m, 20m, 30m or as required

- Temperature Range

- -20°C to +70°C

- Burst Pressure

- up to 60 bar

- End Fittings

- Brass couplings or as specified

Rubber Welding Hoses Trade Information

- Minimum Order Quantity

- 10 Meters

- Supply Ability

- 100 Meters Per Day

- Delivery Time

- 1 Week

About Rubber Welding Hoses

Versatile Hose Solutions for Welding Needs

Designed specifically for gas welding and industrial gas distribution, these rubber hoses offer flexibility in length and diameter to suit diverse applications. Their high tensile synthetic yarn reinforcement ensures durability, while brass end fittings provide secure connections, supporting smooth weld operations across varied settings.

Quality Engineering for Safety and Performance

Each hose undergoes thorough quality inspection to meet rigorous industry requirements. The abrasion and weather-resistant tube extends longevity, making them ideal for both indoor workshops and outdoor environments. Their consistent performance under high pressure safeguards equipment and optimizes worker safety.

FAQs of Rubber Welding Hoses:

Q: How should rubber welding hoses be properly maintained to maximize their lifespan?

A: Regularly inspect hoses for signs of wear, cracks, or leaks, and ensure connections with brass fittings remain tight. Store them away from direct sunlight and corrosive chemicals, and avoid kinking during use or storage to prolong the hoses durability.Q: What are the primary uses for these rubber welding hoses?

A: These hoses are primarily used for conveying oxygen and acetylene gases in manual gas welding equipment and are suitable for various industrial gas processes due to their high resistance to weather, abrasion, and elevated pressures.Q: When is it necessary to replace the welding hose?

A: Replace the hose immediately if you notice any damage, bulging, or stretching beyond normal dimensions, or if the hose fails a pressure or leak test. Routine checks before each use are recommended to ensure operational safety.Q: Where can these hoses be sourced or customized?

A: You can obtain or customize these hoses through authorized distributors, suppliers, or traders in India. Custom requests regarding length, diameter, and fittings are typically accommodated to meet specific project requirements.Q: What makes these hoses suitable for harsh industrial environments?

A: Their synthetic rubber construction, reinforced with high-tensile yarn, provides excellent resistance to weather, abrasion, and pressure changes, making them dependable for continuous use in both indoor and outdoor industrial settings.Q: What benefits do color-coded hoses provide in welding operations?

A: Color coding (red for acetylene, blue for oxygen) helps prevent gas mix-ups, increasing safety and making it easier for workers to identify and handle the correct hose during setup and usage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welding Cables and Hose Pipes Category

Insulated Welding Cables

Price 1 INR

Minimum Order Quantity : 10 Meters

Diameter : Available in various diameters as per specification

Material : Copper Conductor, PVC Insulation

Condition : New

Automation Grade : Manual

Gas Welding Hose Pipe

Price 1 INR

Minimum Order Quantity : 10 Meters

Diameter : 8 mm (other diameters may be available)

Material : Rubber, Reinforced PVC

Condition : New

Automation Grade : Manual

Gas Cutting Hose Pipe

Price 1 INR

Minimum Order Quantity : 10 Meters

Diameter : 6mm, 8mm, 10mm (Customizable)

Material : Synthetic Rubber / PVC Reinforced

Condition : New

Automation Grade : Manual

SS Flexible Hose Pipe

Price 1 INR / Meter

Minimum Order Quantity : 10 Meters

Diameter : 1/4 inch to 12 inch

Material : Stainless Steel (SS)

Condition : New

Automation Grade : Manual

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese