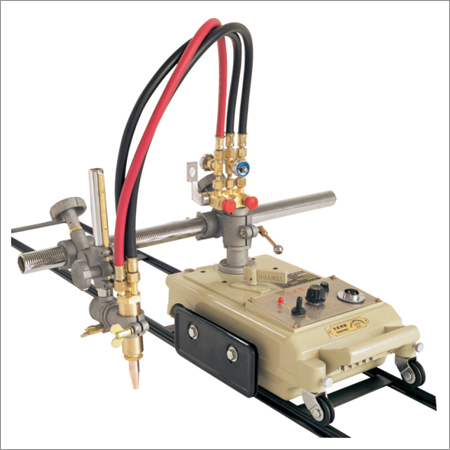

Latest Technology Portable Gas Cutting Machines

MOQ : 10 Meters

Latest Technology Portable Gas Cutting Machines Specification

- Diameter

- Cutting up to 100 mm thickness Millimeter (mm)

- Power Source

- Electric

- Automation Grade

- Semi-Automatic

- Phase

- Single Phase

- Application

- Plate cutting, shape cutting, metal fabrication workshops

- Frequency

- 50/60 Hz Hertz (HZ)

- Power Consumption

- Approx. 100W Watt (W)

- Output Voltage

- 24V (Rail motor output) Volt (V)

- Equipment Type

- Portable Gas Cutting Machines

- Type

- Portable Gas Cutting Machine

- Condition

- New

- Motor Type

- AC Motor

- Material

- Stainless Steel Body with Aluminium Rail and Brass Torch Parts

- Power

- 80-100 W Watt (w)

- Voltage

- 220V Volt (v)

- Dimensions

- L 410 x W 210 x H 170 mm Millimeter (mm)

- Input Voltage

- 220V AC 10% Volt (V)

- Rated Current

- 0.43A Ampere (amp)

- Rated Capacity

- Oxy-Fuel up to 100 mm thickness

- Drive System

- Mechanical drive, geared motor

- Safety Features

- Flashback arrestors, anti-backfire safety design

- Cutting Nozzle Type

- Compatible with A & PNM nozzles

- Ignition Type

- Manual

- Weight

- 10.5 kg Approx.

- Gas Used

- Oxygen + Acetylene or LPG

- Finish

- Anti-corrosive surface treatment

- Operational Mode

- Manual/Automatic

- Cutting Speed

- 50-1000 mm/min variable

- Track Length

- 1.8 meters standard, extendable

- Operating Temperature

- -5C to +50C

- Standard Accessories

- Rail, torch, hose, connectors, tool kit

- Portability

- Heavy-duty handle and compact design for easy movement

- Torch Adjustment

- Multi-directional (Horizontal & Vertical Adjustment)

Latest Technology Portable Gas Cutting Machines Trade Information

- Minimum Order Quantity

- 10 Meters

- Supply Ability

- 100 Meters Per Day

- Delivery Time

- 1 Week

About Latest Technology Portable Gas Cutting Machines

We are considered as one of the reputed companies engaged in supplying Portable Gas Cutting Machines. These are capable of providing 40% higher productivity than conventional machines and thus are preferred more. Different quality tests are performed on varied parameters before delivering it to the customers. These machines are suitable for cutting different materials including iron, steel, and mild steel. Its components such as machine body, rail and crossbar dont require measuring tools, which makes the setup process easier. Thus, the installation process with these machines become easier due to their compact size and portability. Portable Gas Cutting Machines are used in brazing, heating, and welding.

Precision and Adaptability for Industrial Use

Ideal for metal fabrication workshops, this gas cutting machine features multi-directional torch adjustment and a mechanical drive system powered by a geared AC motor. Its semi-automatic operational mode offers both manual and automatic control, making it suitable for intricate as well as routine cutting applications. With a 100W power rating and compatibility with a single-phase 220V supply, it supports robust performance in demanding settings.

Advanced Safety and User Convenience

Safety remains paramount with built-in flashback arrestors and anti-backfire safety mechanisms. The anti-corrosive finish and durable stainless steel construction ensure longevity, while the portability enabled by a compact, lightweight design means easy relocation within the workspace. Standard accessories include a rail, torch, hose, connectors, and a tool kit for immediate set-up.

FAQs of Portable Gas Cutting Machines:

Q: How does the portable gas cutting machine accommodate different cutting requirements?

A: The machines cutting speed is variable between 50 to 1000 mm/min and torch adjustment is multi-directional, allowing both horizontal and vertical changes for versatile plate and shape cutting up to 100 mm thickness. The standard 1.8-meter rail can be extended as needed for larger workpieces.Q: What gases and nozzle types can be used with this cutter?

A: It is compatible with Oxygen combined with Acetylene or LPG, offering flexibility in fuel choice. The torch supports both A & PNM nozzle types, allowing the user to select the best fit for specific cutting requirements.Q: When is it recommended to use the manual versus automatic operational mode?

A: Manual mode is beneficial when precise, hands-on control is needed, especially for irregular shapes or small modifications, while automatic mode streamlines repetitive or long, straight cuts for efficiency.Q: Where can this portable gas cutting machine be utilized?

A: Its compact and heavy-duty design with an anti-corrosive surface makes it suitable for metal fabrication workshops, construction sites, and any setting requiring reliable, portable plate or shape cutting.Q: What is the safety process integrated into the machine?

A: The cutter is fitted with flashback arrestors and features an anti-backfire design, significantly reducing the risk of flame reversal and gas leaks, providing safety for both the operator and equipment during use.Q: How does the machines portability and structural design benefit operators?

A: Weighing approximately 10.5 kg and featuring a robust handle, the machine is easy to transport and reposition. Its stainless steel and aluminium construction ensures durability while remaining lightweight enough for frequent movement.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Gas Cutting and Welding Equipments Category

CNC Portable Gas Cutting Machines

Price 1 INR

Minimum Order Quantity : 10 Meters

Type : CNC Portable Gas Cutting Machine

Condition : New

Material : Mild Steel Body

Automation Grade : Automatic

Gas Cutting Torch Nozzle

Price 1 INR / Meter

Minimum Order Quantity : 10 Meters

Type : Gas Cutting Torch Nozzle

Condition : New

Material : Copper Alloy

Automation Grade : Manual

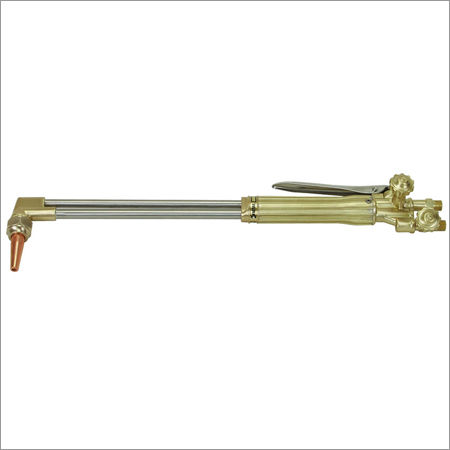

Gas Cutting Torch

Price 1 INR / Meter

Minimum Order Quantity : 10 Meters

Type : Handheld Gas Cutting Torch

Condition : New

Material : Brass and Stainless Steel

Automation Grade : Manual

Gas Welding Cutting Torch

Price 1 INR

Minimum Order Quantity : 10 Meters

Type : Cutting Torch

Condition : New

Material : Brass/Steel Body

Automation Grade : Manual

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese