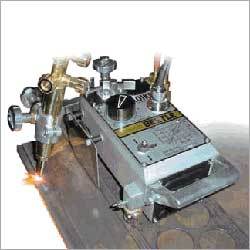

Gas Cutting Torches

Gas Cutting Torches Specification

- Power Source

- Oxygen & LPG/Acetylene Gas

- Welding

- Suitable for Cutting Only

- Equipment Type

- Gas Cutting Torch

- Automation Grade

- Manual

- Application

- Heavy-Duty Metal Cutting in Industrial/Workshops

- Diameter

- Torch Tip Diameter: 1.5 mm to 3 mm

- Type

- Manual Gas Cutting Torch

- Condition

- New

- Motor Type

- Hand Operated

- Material

- Brass Body with Stainless Steel Nozzle

- Dimensions

- Length: 450 mm (approx)

- Rated Capacity

- Designed for up to 300 mm plate thickness

- Torch Length

- 450 mm

- Handle Type

- Ergonomic, Non-Slip Grip

- Operating Temperature

- Up to 3,200°C (cutting zone)

- Flame Adjustment

- Precision Adjustment Knobs

- Pressure Range

- Oxygen: 2-4 bar, Fuel Gas: 0.2-1 bar

- Weight

- Approx. 0.8 kg

- Nozzle Size

- Changeable depending on plate thickness

- Gas Inlet Connections

- Standard 3/8" BSP

- Compatible Gases

- Oxygen, Acetylene, LPG

- Cutting Capacity

- Up to 300 mm Mild Steel

- Ignition Method

- Manual Flame

Gas Cutting Torches Trade Information

- Minimum Order Quantity

- 10 Meters

- Supply Ability

- 100 Meters Per Day

- Delivery Time

- 1 Week

About Gas Cutting Torches

Owing to dedication and expertise of our skilled professionals, we have emerged in this domain as one of the successful traders, stockists and authorized dealers of Gas Cutting Torches in a short span of time. The offered cutting Torches are the best suitable for cutting ferrous metals with oxy-ay or oxy-fuel gases, only difference is of nozzles. Our provided Gas Cutting Torches are made available in 90o angle cutter (general use) 180o angle head cutter with extra long (special purpose)

Exceptional Cutting Performance

This gas cutting torch effortlessly slices through mild steel plates of up to 300 mm thickness, thanks to its durable build and precision flame control. The adjustable pressure range and nozzle sizes allow operators to fine-tune the tool for various industrial applications, maximizing versatility and accuracy.

User-Friendly Design for Safe Handling

Equipped with an ergonomic, non-slip handle, the torch offers a comfortable and secure grip, reducing the risk of operator fatigue and ensuring stability during extended use. The straightforward manual ignition and precision adjustment knobs provide the user with easy, safe, and controlled cutting operations.

Adaptable and Durable Construction

Featuring a brass body and stainless steel nozzle, this gas cutting torch is built to withstand demanding industrial conditions. The 450 mm length provides optimal reach and control, while the changeable nozzle accommodates a range of metal thicknesses, making it a dependable solution for consistent, high-quality cuts.

FAQs of Gas Cutting Torches:

Q: How do I ignite the gas cutting torch manually?

A: To ignite the torch, open the gas valves according to the recommended pressure (Oxygen: 2-4 bar, Fuel Gas: 0.2-1 bar) and use a flint striker or spark lighter near the nozzle. Adjust the flame using the precision adjustment knobs to achieve the desired cutting temperature before starting work.Q: What types of gases are compatible with this torch?

A: The torch is compatible with oxygen and either acetylene or LPG fuel gases. You can choose the appropriate fuel based on availability and application, ensuring both flexibility and efficiency in various industrial cutting tasks.Q: When should I change the nozzle size on the torch?

A: Change the nozzle size when cutting plates of differing thicknesses. Appropriate nozzle sizes (tip diameter 1.5 mm to 3 mm) ensure optimal flame focus and cut quality. Refer to the manufacturers recommendations for selecting the best nozzle for each application.Q: Where can this gas cutting torch be used most effectively?

A: This torch is ideal for heavy-duty metal cutting in industrial plants, fabrication workshops, shipyards, and construction sites across India, providing reliable performance wherever demanding metal-cutting operations are required.Q: What is the process for adjusting the flame while cutting?

A: Flame adjustment is handled via precision adjustment knobs on the handle. Fine-tune the oxygen and fuel gas flows to achieve a neutral or sharp-cutting flame suitable for the material thickness. Always check for a steady flame before proceeding with the cut.Q: What benefits does the ergonomic handle offer during use?

A: The ergonomic, non-slip handle minimizes fatigue, enhances control, and provides a secure grip. This design ensures operator comfort and steady guidance throughout extended cutting sessions, leading to safer and more efficient work results.Q: How does the torchs construction enhance durability?

A: The torch has a brass body with a stainless steel nozzle, offering excellent resistance against heat, corrosion, and wear. This robust construction guarantees longevity and reliability even in harsh industrial conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Cutting and Welding Equipments Category

Portable Gas Cutting Machines

Price 1 INR

Minimum Order Quantity : 10 Meters

Application : Metal Plate Cutting, Industrial Fabrication, Manufacturing

Condition : New

Diameter : Torch: suits nozzle diameters 1.2mm 3mm

Type : Portable Gas Cutting Machine

Cnc Gas Cutting Machines

Price 1 INR

Minimum Order Quantity : 10 Meters

Application : Profile Cutting, Plate Cutting, Fabrication Shops, Steel Plants, Heavy Engineering

Condition : New

Diameter : Customized

Type : CNC Gas Cutting Machine

Gas Welding Cutting Torch

Price 1 INR

Minimum Order Quantity : 10 Meters

Application : Industrial and Workshop Metal Cutting

Condition : New

Diameter : Standard Nozzle Size

Type : Cutting Torch

Gas Welding Pipe

Price 1 INR

Minimum Order Quantity : 10 Meters

Application : Gas Welding, Industrial Piping, Fabrication

Condition : New

Diameter : Varies (commonly 1/2 inch to 2 inch)

Type : Gas Welding Pipe

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese